Jack Thibaudier

Important part of the turnover

Reesink Staal has a reputation in this area. That is why it is important to continuously adapt our processes to changing market demands. We had to take things to the next level, because we were in danger of falling behind in our machining processes. That posed a threat to our customer service and caused frustrations. If we wanted to avoid delays, maintenance of our machines had to improve. The machines used across the six machining processes experienced too much unscheduled downtime. Reesink depends on machining processes for an important part of its turnover. It made sense to implement improvements in this area. Surpex had already knocked on Reesink’s door and now was the time to open that door. I sat down with Ryan Ordelmans. Being aware of his expertise, I knew that we needed him here. Surpex knows the processes, the machines and the market and has pragmatically achieved important milestones here.”

An ingenious system

Thibaudier indicated that work pressure was high at Reesink. There was no time for maintenance and too few people were available. This, in turn, put pressure on machine availability. “We first cut back to two shifts and made some internal adjustments. Surpex then systematically divided the machinery into six process flows and implemented this throughout the company. This way we were all speaking the same language. Corrective maintenance was then performed in all six processes. We gratefully deployed Surpex’ network to do so. Surpex can get things done that we would not have been able to do on our own. Surpex guided us closely during the implementation of autonomous maintenance and trained all those involved. Now we know exactly how to use every individual machining step in an optimal manner, as well as do’s and dont’s, and what needs to be done on a daily, weekly, monthly and annual basis. Using a simple but ingenious system with magnets, every team can see whether maintenance was actually carried out. ” The employees and the machinery are now ready for the future, but can also continue to develop based on market demand. The costs of the machining processes have become transparent and predictable, which is key to our commercial success.

A consultant who knows the business and the machines

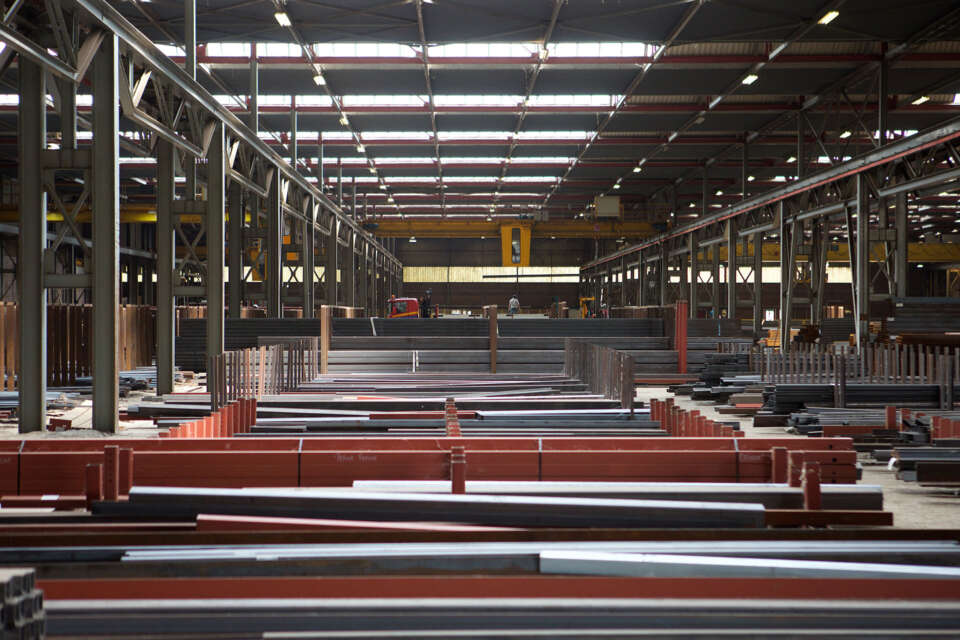

Reesink has always been a pioneer in adding machining steps to the steel trade. In the sixties they were already providing cutting services, and twenty years ago the company chose to include drilling as well. By combining this with a very wide product range and enormous inventories (the hall covers an area of 30,000 m2), the company managed to build up a large customer base and a good reputation within a radius of approximately 150 km around Zutphen. Thibaudier: “But if you want to stay in the lead, you have to keep investing in the quality of your machines. This made it possible to take a leap in our machining processes. This included circular saws and drills, fraying, blasting and preserving. I earmarked a budget, but immediately realised that a consultant who knows the business and the machines, and who can and wants to go beyond maintenance was required. Surpex really outperformed. Within a tight schedule and remaining within the budget, we were able to upgrade our machinery to the level we wanted. We have literally gone to practically zero downtime. Surpex has proven that it can pragmatically achieve success based on its expertise in processes, machines and market knowledge. This way, our customer service remained excellent.”

A cultural shift at the whole company

Surpex was also consulted for preventive maintenance to avoid future malfunctions. This included plans for the technical department, but also, for example, an inventory of the crucial spare parts that had to be in stock at all times in order to prevent prolonged downtimes in the event of malfunctions. Thibaudier: “Ryan Ordelmans personally trained the employees in the technical department in the inventorying and planning of maintenance and the prevention of downtime. He is aware of the problems they may encounter and really knows how to involve them in his story. All in all, the production train is now running optimally. Surpex correctly pointed out to us that excelling in both steel trade and processing requires a cultural shift at the entire company. For value added cooperation, we need specialists not only in production, but throughout the whole company, who know the processes that Reesink Staal manages. After all, you can sell double the amount of steel next week, but not double the amount of processing.”

Thibaudier looks back on the process he was able to initiate with satisfaction: “I am very happy with what we have achieved here. We were able to make a leap forward in a short timeframe. The contribution that Surpex has made was substantial. Reesink Staal will continue to rely on Surpex’ expertise and broad professional network.”