Martijn Doeschot

- Operational excellence has been achieved within the company

- Autonomous maintenance has been introduced and, in parallel, availability problems have been solved together with the machine supplier.

- A process and activity analysis provided insight, awareness and understanding

- Tasks, responsibilities and powers have been allocated, processes defined and transitions agreed upon

- By means of 5S and visualisation, workplaces and logistic locations are clearly indicated.

Many changes in 45 years

In the past 45 years Doeschot BV has changed a lot. Frans Doeschot started the metal company specialising in agricultural mechanisation. In addition to the agricultural sector, he also gained clients in the construction and supply industry. Since 1995 Frans runs the company together with his sons Roy and Martijn. Through innovative and progressive entrepreneurship, the company has developed into a metalworking company with two activities;

- (Turn-key) Structural steel work and roof and wall cladding

- Supply, construction & plate processing

The team with which the company offers the work has also grown considerably over the years. From just a father and two sons, it went to 40 people, says Martijn: "When we were growing really fast and we were getting more and more work, we created the breakdown into divisions. As a result, the planning went better and we got everything running properly”.

From maintenance to much more

The reason for the contact between Doeschot BV and Surpex was the purchase of a new highly automated steel processing machine. Martijn: "We received a message from Surpex to talk about the maintenance of our saw/drill line. At first I thought we could do that ourselves, but they were insistent and wanted to meet and talk. That was a good conversation and one thing led to another. From the subject of maintenance we came to work efficiently, LEAN and that everyone should be facing the same direction”. -creating value and eliminating waste-

For various reasons, the mentioned steel processing machine was insufficiently reliable, available and productive.

- Reliable: insufficient due to unclear process boundaries, automatic infeed and outfeed, ownership & maintenance.

- Available: many machine-related technical and software malfunctions

- Productive: imperfections in logistic control, drawing room/work preparation, planning and production activities

Efficiency improvement implemented

The capabilities of this machine made it necessary to adapt the execution of the operations. Existing work preparation, planning and operating activities were disrupted and irritation arose between employees and departments. Martijn: "There were a lot of things we could improve in the office. Surpex handled that very well, because we definitely benefited from the efficiency gains we achieved together. That also applies to the maintenance of our machines. We have now managed to do that very well. It makes a difference whether Surpex says something to an employee or I say it. We are happy with their experience and knowledge, but also with their network. They have put some pressure on it, so that the problems with our machine software have been solved. The maintenance is now much better, which means the machine will also last longer.

we definitely benefited from the efficiency gains we achieved together

Clearer and more efficient

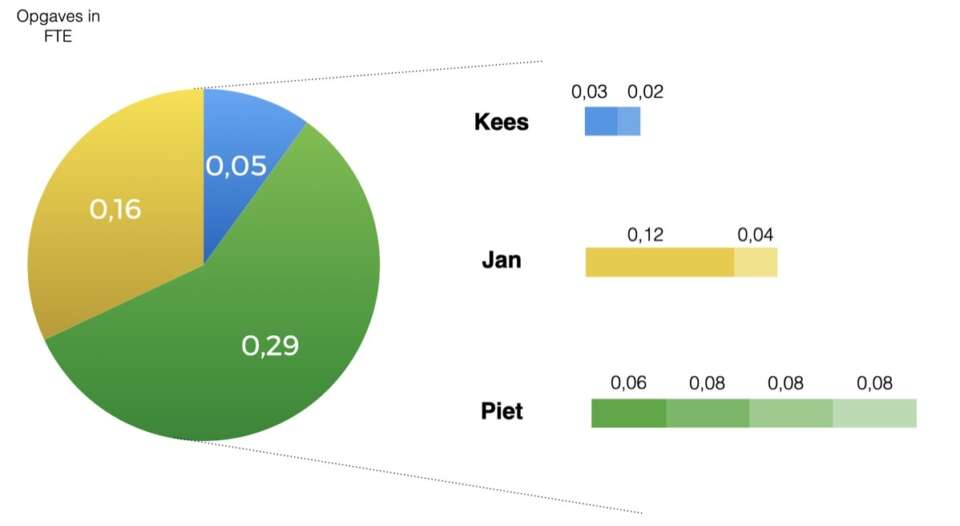

Finally great improvements were realized at Doeschot BV by Surpex. By means of a process and activity analysis, insight was gained into who actually carried out which activities and how much time this took. This resulted in awareness and understanding. Subsequently, tasks, responsibilities and authorities were assigned, processes were outlined and transfers were agreed upon. By means of 5S and visualization, workplaces and logistic locations were clearly indicated. Autonomous maintenance was introduced and, in parallel, availability problems were solved together with the supplier.

Martijn: "It has now become much clearer to us in the office who is doing what and who is responsible for what. It sounds very simple to have a job description for every employee, but we didn't have that before. That's why it now works much more smoothly and efficiently. Everything on the work floor now has its own fixed place with lines on the floor. We order on time and not too much at once. But also, for example, not having the steel delivered until 10.00 a.m., so that we have enough time to fill the machine's automatic infeed system and have the machine up and running.

Advisor from the industry

Doeschot BV is very satisfied with the cooperation with Surpex, says Martijn: "As an industry consultant Surpex is strong in business development and coming up with efficient solutions. I can certainly recommend other companies to involve Surpex. There is much more to it than optimizing maintenance.

There is much more to it than optimizing maintenance